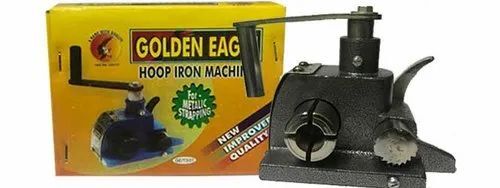

Strapping Tensioner and Strap Sealer

1500 INR/Set

Product Details:

- Type Strapping Tensioner and Strap Sealer

- Material Iron

- Automatic Grade Manual

- Dimension (L*W*H) 12 mm to 19 mm Millimeter (mm)

- Color Red, Black etc.

- Click to View more

X

Strapping Tensioner and Strap Sealer Price And Quantity

- 1 Set

- 1500 INR/Set

Strapping Tensioner and Strap Sealer Product Specifications

- Red, Black etc.

- Strapping Tensioner and Strap Sealer

- Manual

- Iron

- 12 mm to 19 mm Millimeter (mm)

Strapping Tensioner and Strap Sealer Trade Information

- 5000 Set Per Month

- 7 Days

Product Description

A strapping tensioner and strap sealer are essential tools used together in the packaging and shipping industry to securely seal and tighten strapping also known as banding or bundling around packages or loads Heres how each tool functions

1 Strapping Tensioner

Purpose The strapping tensioner is used to tighten the strapping around the package or load It typically has a ratcheting mechanism or another method to apply tension to the strapping material

Operation The tensioner grips the strapping and allows the user to pull it tight manually It maintains tension while the strapping is being secured with seals or buckles

Types There are different types of tensioners depending on the material of the strapping eg polyester polypropylene steel and the application eg handheld tensioners pneumatic tensioners for highvolume operations

2 Strap Sealer or Crimper

Purpose The strap sealer is used to crimp or seal the ends of the strapping together after it has been tensioned

Operation After the tensioner has tightened the strapping around the package or load the strap sealer is used to crimp a metal seal around the overlapping ends of the strapping This creates a secure closure that prevents the strapping from loosening

Types Sealers come in various designs depending on the type and width of the strapping being used They may be manual handheld tools or powered tools for higher efficiency

3 Workflow

First the strapping tensioner is used to tighten the strapping around the package or load

Once the desired tension is achieved the strap sealer is used to crimp a metal seal onto the strapping securing it in place

Some applications may also use a cutter tool to trim excess strapping after sealing

4 Applications

Strapping tensioners and sealers are used in various industries including shipping logistics warehousing and manufacturing

They are used to secure packages on pallets bundle products together reinforce packaging for transportation and more

5 Safety Considerations

When using these tools its important to follow safety guidelines to prevent injury or damage

Wear appropriate protective gear such as gloves and eye protection

Ensure proper training in tool operation to minimize risks

These tools are crucial for ensuring that packages and loads are securely strapped for safe transportation and handling When choosing tensioners and sealers consider the specific requirements of your application including the type and size of strapping material youll be using and the volume of packaging operations youll be handling

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Manual Packing Tools' category

|

PAYAL ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |